ENCN

Home / Membrane materials | Comparison of ETFE, STFE, and PTFE high-transmittance membranes

Membrane materials | Comparison of ETFE, STFE, and PTFE high-transmittance membranes

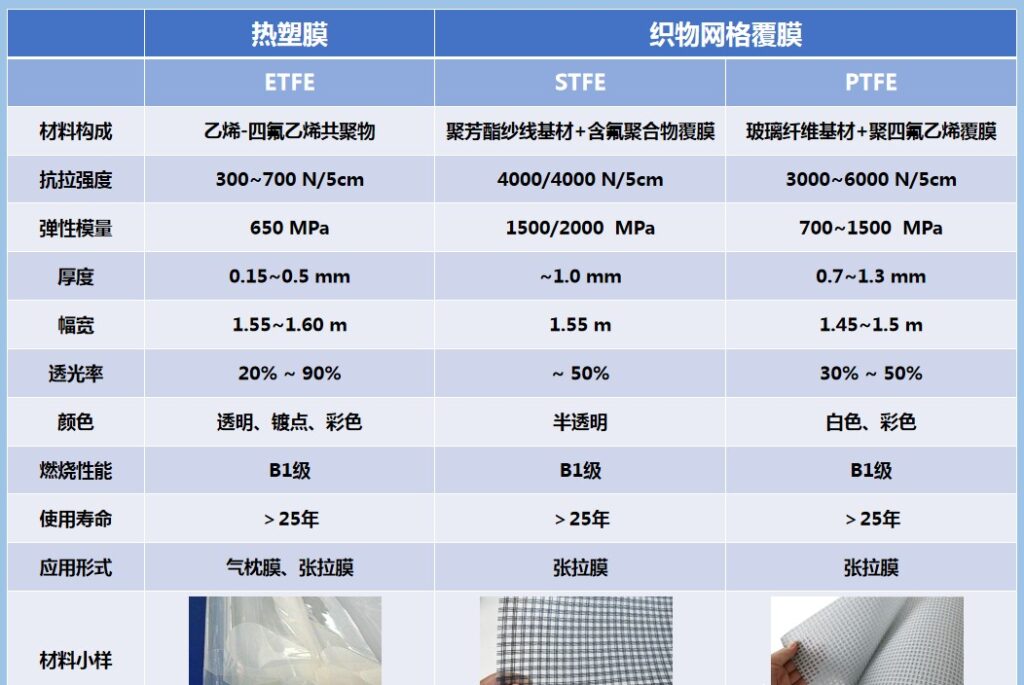

In the design stage of buildings and structures, when choosing membrane materials with high light transmittance, people often have difficulty in grasping the characteristics of different types of membrane materials. In response to this problem, the characteristics of ETFE, STFE, and PTFE high-transmittance membranes are sorted out in detail, in order to provide reasonable and well-founded technical support for the selection of high-transmittance membranes.

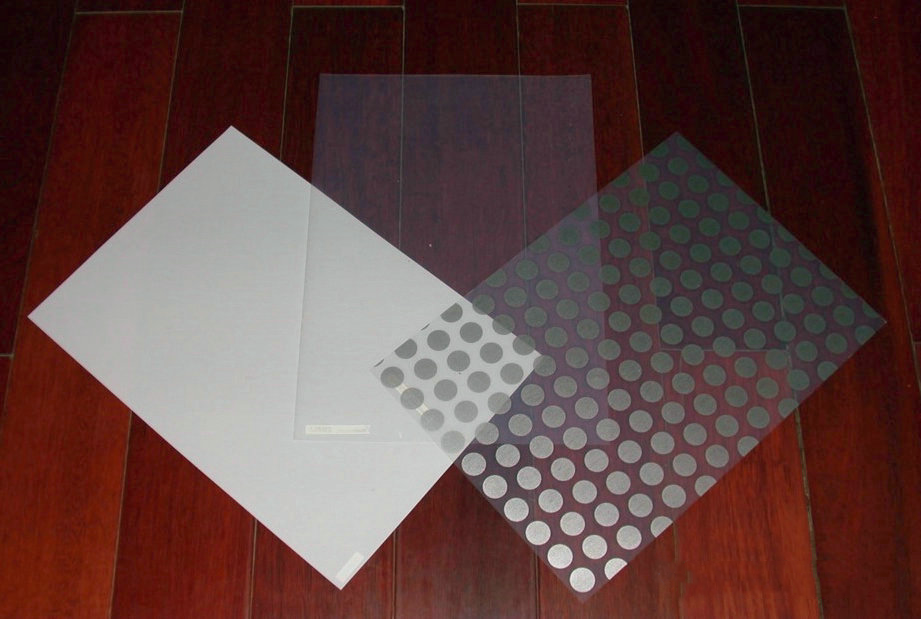

ETFE membrane materials have no fabric substrate and are directly composed of thermoplastic compound films. They are ETFE (ethylene-tetrafluoroethylene copolymer) powder or particles heated to above 380 degrees Celsius to reach a molten resin slurry, which is extruded by hot pressing wheels and finally formed into a film with standard thickness (0.1~0.5mm) and standard width (1.55~1.60m). High light transmittance (up to 90% for transparent membranes), light and scenery, rich colors (various colors are available, and the light transmittance and shading coefficient can be controlled by plating), good flexibility, very suitable for (air pillow) inflatable membrane structure, and single-layer tensile membrane with small membrane unit area.

STFE is not the abbreviation of chemical composition, but the abbreviation of membrane product name (Structural, Transparent, Fluorinated, Envelope), and its essence is grid coating. The difference lies in its fabric substrate, which is different from the polyester fiber yarn of PVC membrane and the glass fiber yarn of PTFE membrane, but is extruded with a special coating of polyarylate yarn; the coating is a special fluorinated polymer (involving trade secrets not disclosed), and the coating is single-sided. The clarity of the coating is good, and a certain degree of scenery can be achieved. At the same time, the fabric substrate improves the strength of the membrane material, and the tensile strength can reach 4000N/5cm. Even without adding cables, the span of the membrane unit is generally more than 3m.

PTFE grid coating is to increase the yarn grid spacing of the glass fiber substrate and impregnate it with PTFE emulsion to form a grid fabric substrate with a certain open porosity, and then coat the PTFE film on both sides at a specific temperature and specific pressure, and finally shape it into a grid coating material with a certain thickness and width, which is also commonly called high-transmittance membrane. The weaving process of glass fiber yarn is mature, and high-strength fabric substrates can be customized to reach G6 grade. Even without cables, the span of the membrane unit can generally reach about 5m. The initial pre-tension is high, the tensioning is flat, the appearance effect is good, and the durability and self-cleaning property of PTFE are good.

In fact, each membrane material has its own irreplaceable advantages, and at the same time, it has shortcomings that are difficult to overcome for a while. It may not be realistic to have a perfect membrane material. This requires owners and designers to make appropriate trade-offs according to the characteristics of specific projects, make full use of the advantages of a certain membrane material, and make up for its shortcomings through other technical means, so as to make the best use of everything and use the best steel on the blade.

Yexing Company is a professional membrane structure manufacturer and has many cases at home and abroad. If you want to know more membrane structure engineering cases, please visit Yexing official website(https://www.yexingms.com/)or follow our TikTok Account(https://www.tiktok.com/@yexing.group)/ Youtube Account(https://www.youtube.com/channel/UCPosuHguAFSnMm9j_FLU_bg), thank you for your attention.

Membrane materials | Comparison of ETFE, STFE, and PTFE high-transmittance membranes

Recent News

-

Introduction to the entire process of membrane structure

-

Yexing – International Financial Forum (IFF) Permanent Site Membrane Structure Engineering

-

Yexing—Huizhou Zhonghai Plaza ETFE Sky Screen Membrane Structure Project Introduction

-

New news丨The cloud waiting hall of Hangzhou West Railway Station is about to be put into operation