Director of Yexing

Membrane Structure Design

ENCN

ENCN

Home / Projects / Xiamen New Sports Center Egret Stadium Membrane Structural engineering

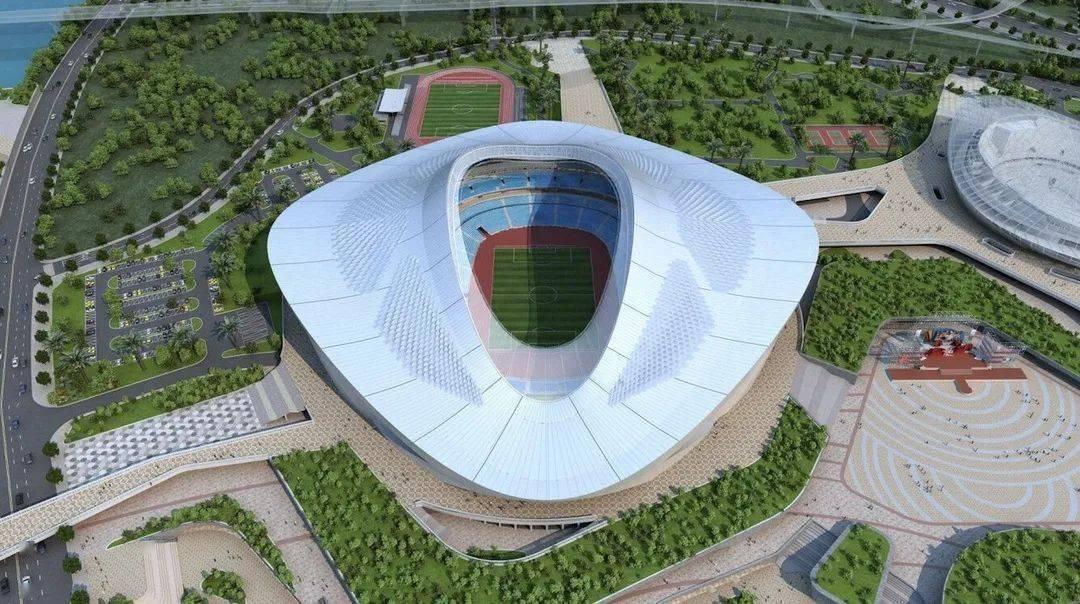

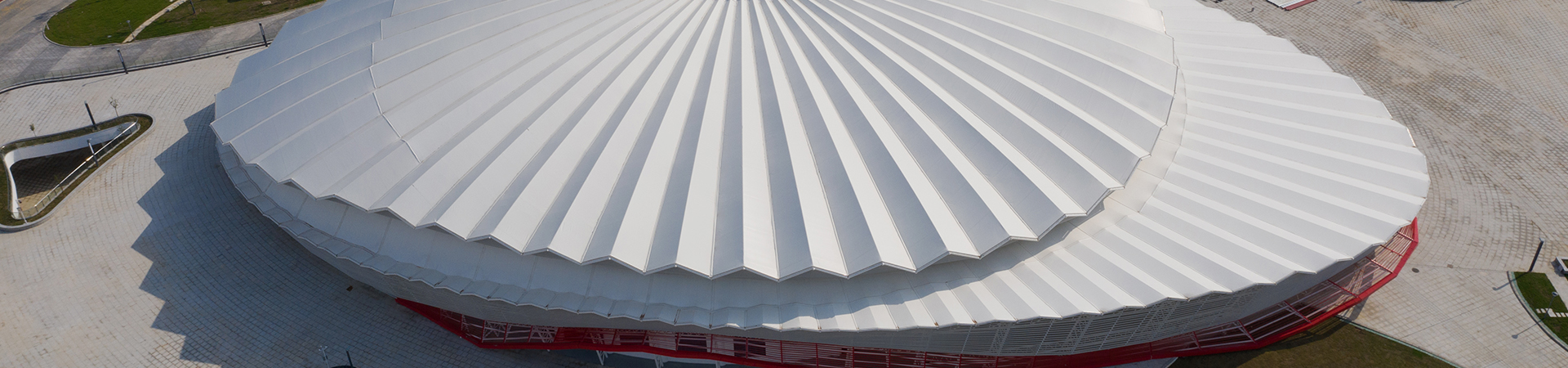

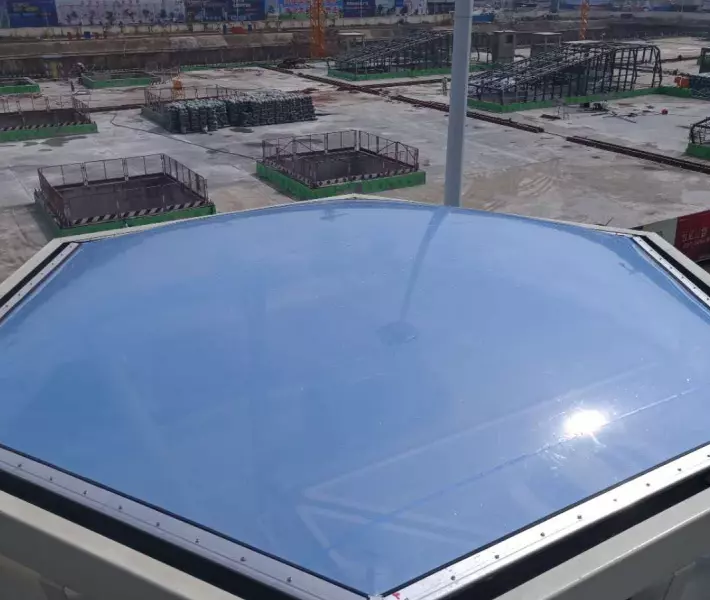

The Egret Stadium at the Xiamen New Sports Center of the Asian Cup is the first in China and the third in the world to achieve free conversion between professional football fields and comprehensive track and field fields. The football mode seating capacity is about 60000 seats, and the comprehensive track and field seating capacity is about 50000 seats. The total film usage is nearly 60000 square meters, all of which are made of high-strength and environmentally friendly PTFE film imported from Germany. The stadium is 326 meters long from east to west and spans 350 meters from north to south. The south stand has been opened with a width of about 80 meters. Some spectators on the east and north sides can also enjoy beautiful sea views while enjoying the competition.

The giant arch of the stadium adopts a rectangular space pipe truss, which is one of the main load-bearing components of the roof steel membrane structure. The overall inclination is 22 ° towards the outside. The roof steel membrane structure has a large spatial span, high steel processing standards, and difficult lifting construction. The installation height reaches 85m, which is equivalent to the height of a 28 story ordinary residential building. It ranks first in height among the ten Asian Cup hosting stadiums.

Xiamen New Sports Center Egret Stadium Membrane Structural engineering

| Date | 2023 |

|---|---|

| Location | Fujian, China |

| Size | 59,000 m² |

| Membrane | White PTFE film |

| Structure | Framework Membrane Structure |

PTFE film on glass fiber fabric creates durable roofs with over 30 years of lifespan, ideal for sports venues, commercial facilities, and transportation structures.

View Details

The steel structure of the Yexing project has been carefully constructed and installed by force analysis and structural calculation by STAAD, SW, ANSYS, RHINO, 3D3S and other software, and has become a permanent building structure with a life of at least 50 years.

Yexing has 19 years of professional installation experience in steel structure and 15 years of membrane structure, and more than 400+ landing projects at home and abroad are the greatest affirmation of Yexing's construction level.

Imported top brand membrane material, with high tensile strength, large bearing capacity, long service life, bearing capacity per square can reach 300-500KG, wind resistance level 12 or more, upper, seismic resistance above 7 grade.

Yexing adopts imported intersecting wire cutting equipment and first-stream carbon dioxide protection welding equipment, which has good precision, high efficiency, and electric welder certificate. On-the-job, strict assessment, outstanding craftsmanship.

The anti-corrosion and anti-rust process of Yexing film structure is controlled layer by layer through 8 processes: shot blasting, rust removal, sandblasting, 2 primers, intermediate paints and 2 topcoats, and strictly abide by the quality.

Yexing membrane structure accessories are high-quality, all stainless steel or national standard hot-dip galvanized customized standard parts, PE cables are provided by Juli Group, high vanadium cables are provided by Jianlang Group.