ENCN

Home / Control process of membrane structure quality

Control process of membrane structure quality

Membrane structure analyzes the control process of membrane structure quality for you:

First, the high-strength bolted connection should meet the following requirements

The screwing sequence and initial and retightening torque of the high-strength bolt connection pair should meet the design requirements and the provisions of the national current industry standard “Design, Construction and Acceptance Regulations for High-strength Bolted Connections of Steel Structures” JGJ82; The friction surface of high-strength bolt connection should be kept dry, neat, there should be no flashing, burrs, welding spatter, welding scars, iron oxide scale, dirt, etc., in addition to design requirements, the friction surface should not be painted; High-strength bolts should freely penetrate into the bolt hole, the bolt hole should not be reamed by gas cutting, the number of reaming should be agreed by the design, and the hole diameter after reaming should not exceed 1.2d (d is the diameter of the bolt);

Second, high-strength bolt construction quality control

The method of applying and controlling the pre-gara force used in the high-strength bolt connection of the high-strength hexagonal head, the common torque control method uses a special plate hand that directly displays the torque, and the relationship between the tightening torque applied to the bolt and the pre-tension force in the introduced bolt is measured in advance, and the pre-tension force is inferred from the torque value. In order to compensate for the possible relaxation of the tensile force, the applied torque value can exceed 5%~10%. The calibration of the wrench is the focus of construction quality control, and calibration is carried out to clarify the torque indication value. When the calibration is found to exceed the allowable range, the bolts tightened with this wrench should all be regarded as wrenches calibrated before use, and the rental error of mobile toilets should be controlled within ±3% (including calibration with inspection wrench), and the error should not exceed ±5% after use. The processing of the contact surface is also the focus of construction quality control, that is, the steel surface processing of the contact surface of the component, so that the anti-slip coefficient of the outer surface of the contact surface reaches the rated value required by the design, generally 0.45~0.55, and the friction surface treatment method is more, and the better is sandblasting (or shot blasting) treatment. The gap of the contact surface should be strictly controlled, when the gap between the component and the splicing plate surface is greater than 1.0mm, the anti-slip force is reduced by 10%, so the S≤1.0mm can not be treated, more must be treated. The number of temporary bolts and punching nails required for each node should be selected to ensure safety and prevent component drift. Generally, it should not be less than 1/3 of the total number of node bolts, temporary bolts should not be less than 2, and the number of punching nails should not be more than 30% of temporary bolts. High-strength bolts for connection shall not be doubled as temporary bolts. Install and replace high-strength bolts, shall not be forcibly knocked in, and shall not be gas cut and reaming. The contact surface of the component should be kept clean and dry, and should not be operated in the rain.

Initial and final screwing requirements:

Tightening should generally be carried out by the method of tightening the center position of the bolt group node outward in order, and the initial (complex) tightening and final tightening should be marked; The initial screwing (re-tightening) value is taken, and the initial tightening torque of high-strength hexagonal head bolt construction is generally 50%~60% of the final screwing value. It is divided into initial screwing, final screwing, and large nodes are divided into initial screwing, rescrewing and final screwing. The rescrewing torque is equal to the initial tightening torque, and the initial tightening, rescrewing and final tightening should be completed within 24h;

Control process of membrane structure quality

Recent News

-

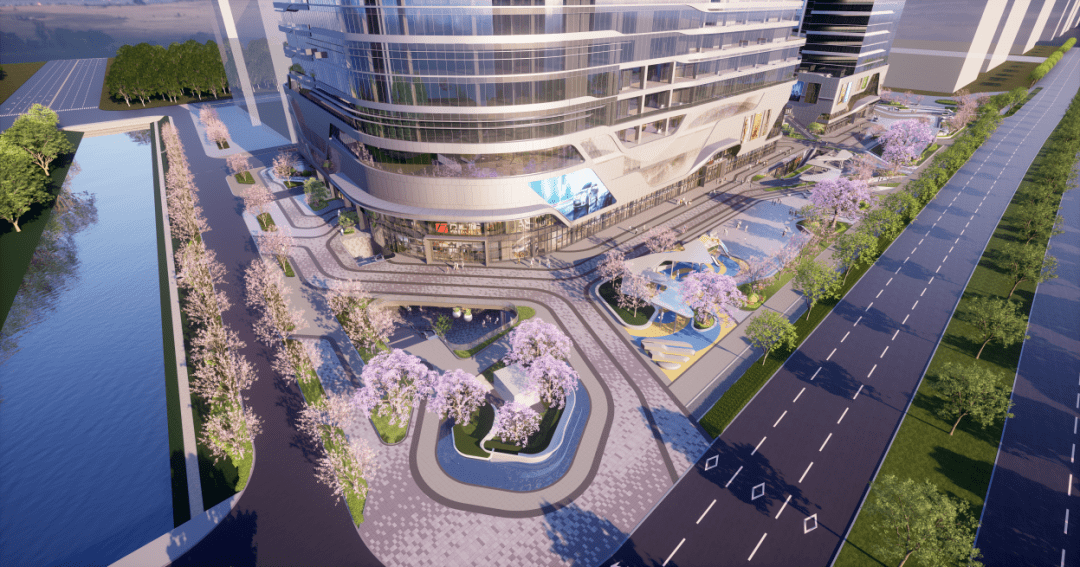

Yexing—Introduction to the latest progress of commercial membrane structure projects in Nanjing Wanhui North District

-

ETFE membrane structure decorative roof of Shandong Weifang High speed Railway Station

-

Introduction to the entire process of membrane structure

-

New Development丨Aid to Belarus National Football Stadium