Need Help to Complete Your Project?

If you need more information about our membrane structure, please feel free to contact us, we will provide you with professional personnel for service, we will reply promptly after receiving the information.

ENCN

Home / Applications

It is composed of membrane materials, steel cables and pillars. The steel cables and pillars are used to introduce tension into the membrane materials to achieve a stable form. In addition to being able to practice creative, innovative and beautiful shapes, it is also the structural form that best demonstrates the spirit of membrane structures. In recent years, large-span spaces also adopt the form of steel cables and compressed materials to form steel cable nets to support the upper membrane. It requires high construction precision, strong structural performance, and rich expressive force.

If you need more information about our membrane structure, please feel free to contact us, we will provide you with professional personnel for service, we will reply promptly after receiving the information.

A professional engineering service provider of membrane structure integrating design, production, construction and installation

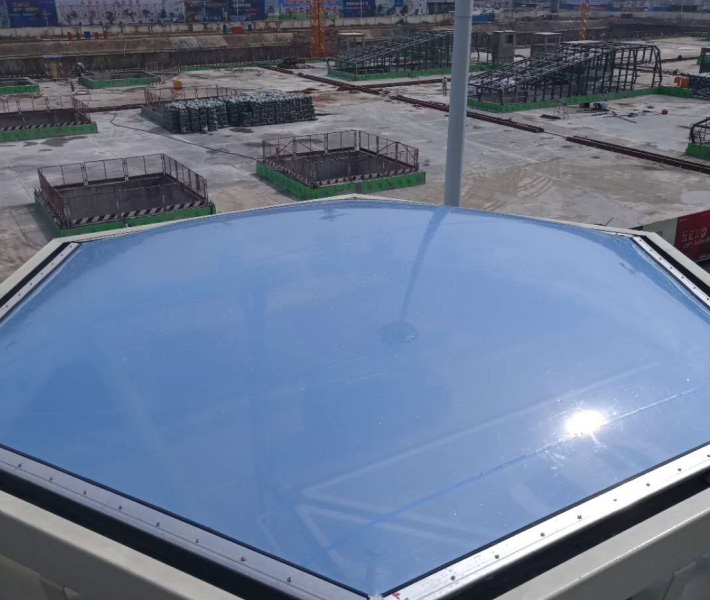

The steel structure of the Yexing project has been carefully constructed and installed by force analysis and structural calculation by STAAD, SW, ANSYS, RHINO, 3D3S and other software, and has become a permanent building structure with a life of at least 50 years.

Yexing has 19 years of professional installation experience in steel structure and 15 years of membrane structure, and more than 400+ landing projects at home and abroad are the greatest affirmation of Yexing's construction level.

Imported top brand membrane material, with high tensile strength, large bearing capacity, long service life, bearing capacity per square can reach 300-500KG, wind resistance level 12 or more, upper, seismic resistance above 7 grade.

Yexing adopts imported intersecting wire cutting equipment and first-stream carbon dioxide protection welding equipment, which has good precision, high efficiency, and electric welder certificate. On-the-job, strict assessment, outstanding craftsmanship.

The anti-corrosion and anti-rust process of Yexing film structure is controlled layer by layer through 8 processes: shot blasting, rust removal, sandblasting, 2 primers, intermediate paints and 2 topcoats, and strictly abide by the quality.

Yexing membrane structure accessories are high-quality, all stainless steel or national standard hot-dip galvanized customized standard parts, PE cables are provided by Juli Group, high vanadium cables are provided by Jianlang Group.