ENCN

Home / Fish Leaping in Shenshan West | Yexing-Changsha Bay Service Area Steel Membrane Structure Project Completed Successfully

Fish Leaping in Shenshan West | Yexing-Changsha Bay Service Area Steel Membrane Structure Project Completed Successfully

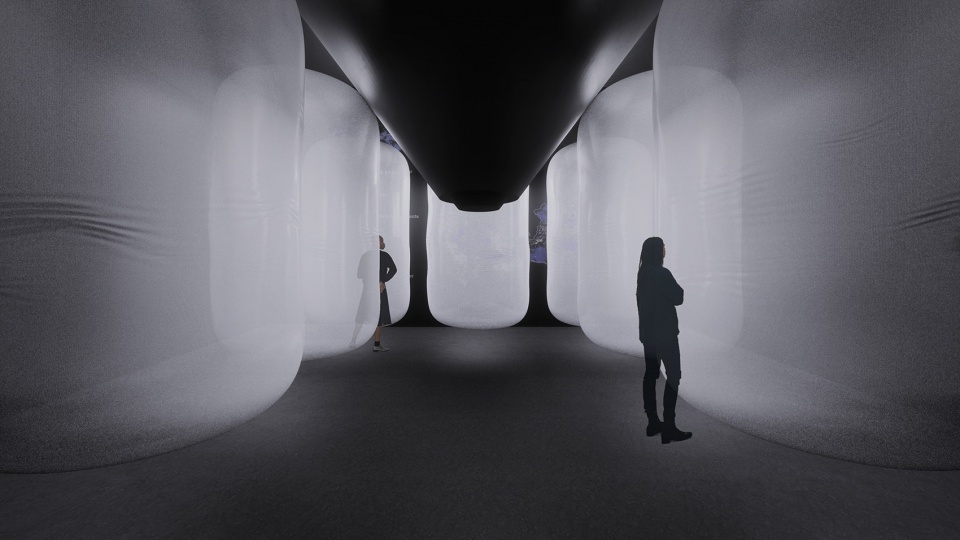

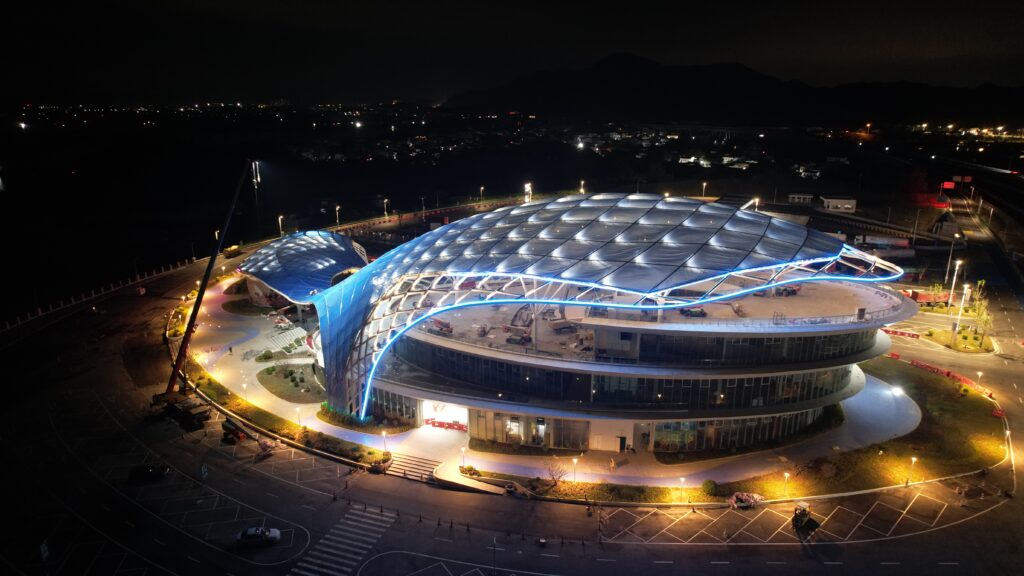

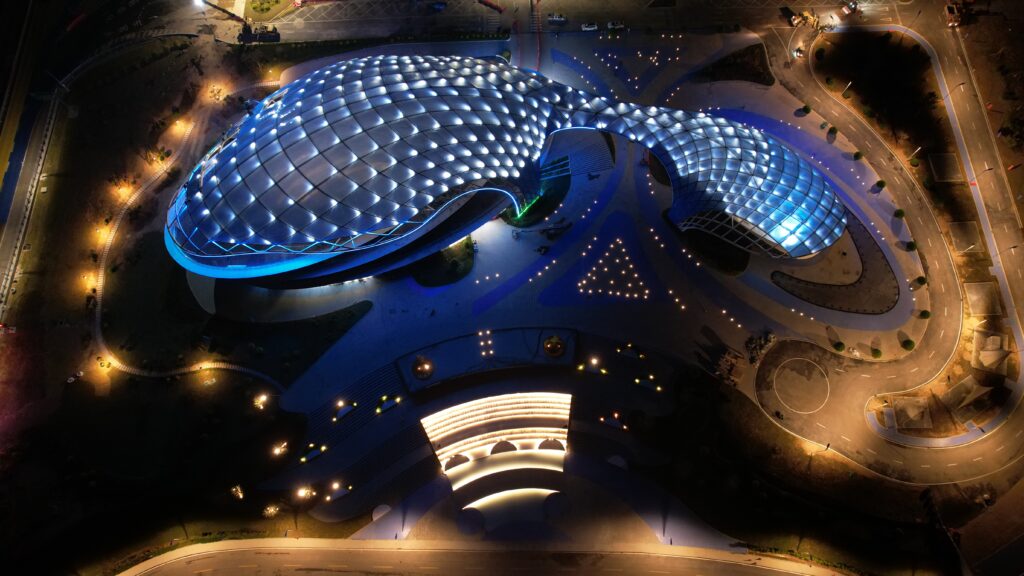

On November 9, the steel membrane structure of the northern area of Changsha Bay Service Area of the Shenzhen-Shanwei West Expressway Expansion Project undertaken by China Railway 14th Bureau was successfully completed, marking that the overall construction of the service area is approaching the final stage and will be officially put into use soon. Previously, the southern area of the service area had completed the construction task ahead of schedule on November 5.

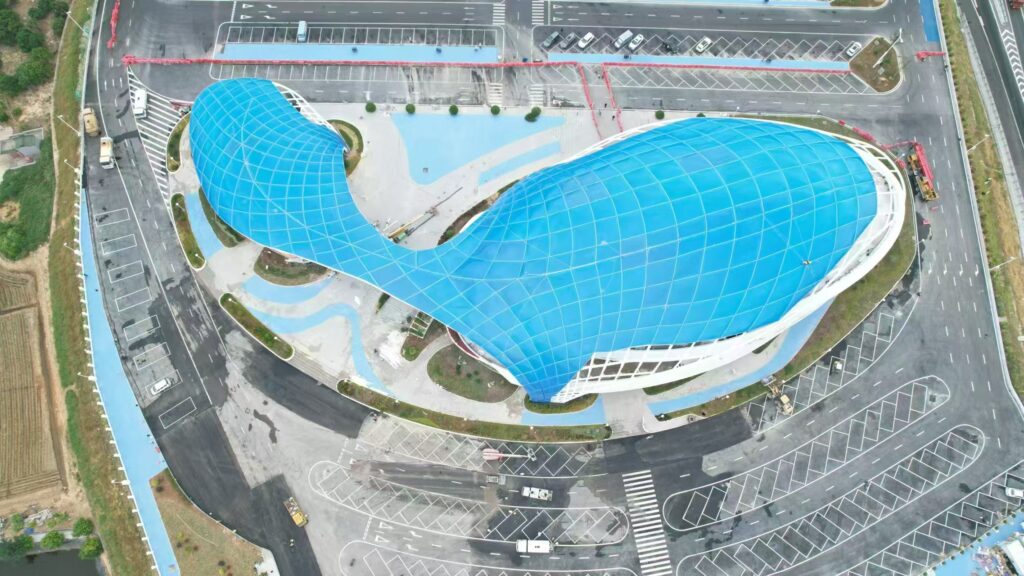

As a key and difficult project of the Shenzhen-Shanwei West Expressway Expansion Project, the service area covers a total area of 350 mu, including 218 mu on the south side and 132 mu on the north side. The main structure adopts steel structure, and the roof is a “net-shaped sky curtain” composed of diamond-shaped grid shell steel structure and membrane structure, forming a leaping whale image. The highest point of the “whale” is 31 meters and the length is 140 meters. The building adopts a special-shaped spatial geometry, its spatial layout presents a curved beauty, and the structural node design is precise and complex. Its innovative design and large-span steel structure construction undoubtedly pose a great challenge to construction technology.

According to the project leader, the steel formwork construction of the service area marks a pioneering engineering practice. This project is a free-form lattice shell structure. In addition to checking the strength, stability and structural stiffness of the lattice shell structure components according to conventional design specifications, the overall stability of the structure and the sensitivity to initial defects should also be checked. How to accurately calculate the stable critical bearing capacity of the structure and determine the impact of various defects on the stability of the structure are issues that must be considered in lattice shell design. It can be seen that the “net canopy” design puts forward extremely high requirements for the control of construction accuracy and structural force analysis.

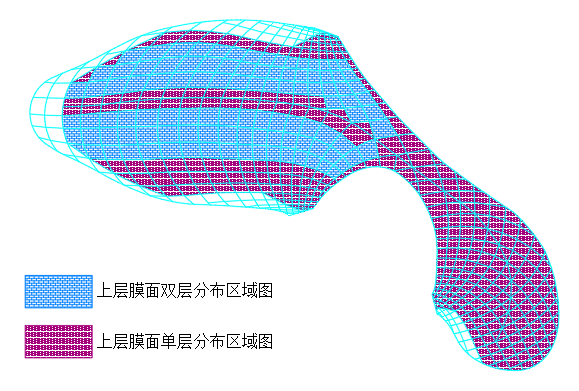

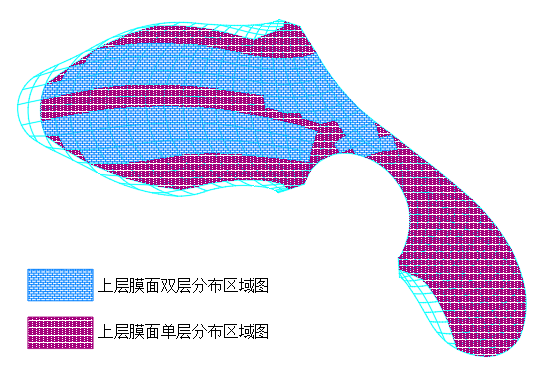

Since the membrane surface of this project is an irregular curved surface and the membrane surface has large fluctuations, the wind load shape coefficients of various areas of the membrane surface are quite different. Therefore, in some areas with relatively large shape coefficients (located on both sides of the fish spine of the fish head and body), a three-layer air pillow membrane with a double layer on the upper layer and a single layer on the lower layer is used, which is equivalent to strengthening the upper layer of this part of the air pillow (the membrane surface load is mainly borne by the upper layer), and a double-layer air pillow membrane with a single layer on the upper layer and a single layer on the lower layer is used in other areas with relatively small shape coefficients. See the figure below for specific areas.

As a professional contractor of steel membrane structure for Changsha Bay Service Area Project of Shenzhen-Shanwei West Reconstruction and Expansion Project, Yexing is responsible for the in-depth design and construction and installation of ETFE air cushion membrane structure roof in the north and south areas of Changsha Bay. The membrane unit grid has undergone several modifications and adjustments from the initial triangle to the hexagon and then to the rhombus. Each time, the scheme and the corresponding construction drawings were given, and the expert review was carried out before the final draft was finally formed. The process can be described as long and tortuous. The project is calculated based on the single-layer membrane expansion area of 6,379 square meters in the north area and 5,975 square meters in the south area, totaling 12,354 square meters. The membrane structure has 451 air cushion units in the north area and 418 air cushion units in the south area. The ETFE membrane materials are all produced and airlifted from Germany.

In order to ensure the efficient advancement of the project construction progress, the company has specially formulated an incentive plan for the steel membrane structure project of Changsha Bay Service Area. Clearly divide personnel responsibilities, implement specific tasks for responsible persons, monitor and analyze project progress in real time, provide precise guidance for construction activities, focus on supporting and optimizing key areas such as technical implementation, safety management, and equipment and material management of the project, and ensure that the project can be delivered safely and with quality and quantity according to the established time nodes.

It is reported that Changsha Bay Service Area is positioned as a commercial and tourism service area, and is an important livelihood project of Guangdong Province’s “Hundred Million Project”. Its completion will greatly enhance the regional service function. The service area will integrate diversified services such as transportation, tourism, sightseeing, consumption and leisure, which will not only optimize the local transportation network, but also provide a new platform for the promotion and sales of characteristic agricultural products. In addition, the construction of Changsha Bay Service Area will effectively activate the economic vitality of the surrounding areas and promote the prosperity and development of the regional economy. It has far-reaching strategic significance for promoting the upgrading of local characteristic industries and the sustainable development of the regional economy.

Yexing Company is a professional membrane structure manufacturer and has many cases at home and abroad. If you want to know more membrane structure engineering cases, please visit Yexing official website(https://www.yexingms.com/)or follow our TikTok Account(https://www.tiktok.com/@yexing.group)/ Youtube Account(https://www.youtube.com/channel/UCPosuHguAFSnMm9j_FLU_bg), thank you for your attention.

Fish Leaping in Shenshan West | Yexing-Changsha Bay Service Area Steel Membrane Structure Project Completed Successfully