ENCN

Home / How to repair the damaged ETFE membrane structure air pillow?

How to repair the damaged ETFE membrane structure air pillow?

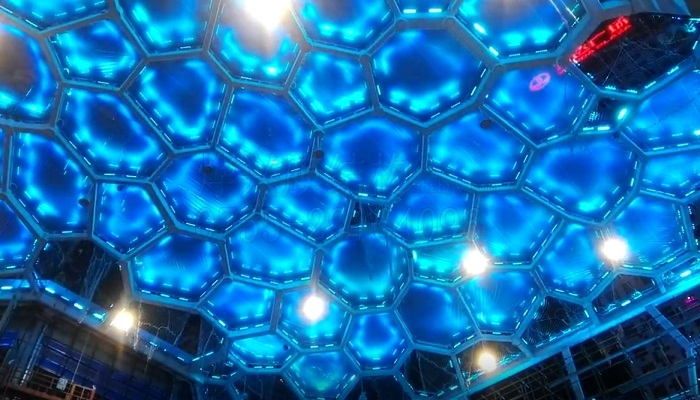

Due to the high strength and toughness of the ETFE membrane structure air pillow, the possibility of damage after installation on walls and roofs is very low, except for non human damage or other unexpected situations. Nevertheless, it is still necessary to consider countermeasures and maintenance plans in the event of damage. Yexing has been focusing on membrane structures for 16 years. This article is a summary of the maintenance experience of ETFE membrane structure air pillow damage by industry experts. We hope it can be helpful to you.

Accidental damage to ETFE air cushions may occur in different situations and degrees, so targeted maintenance measures need to be taken.

Generally, common damages are caused by external force scratches or sharp tool punctures, with different sizes and areas of the damaged surface. For smaller voids (diameter less than 30mm) or elongated scratches, special tape made of ETFE film can generally be used for repair. This type of tape has the same properties as the air pillow film, including mechanical properties, physical and chemical properties, as well as aging and weather resistance. Moreover, the special transparent adhesive applied on it has high bonding strength and excellent weather resistance. The repaired air pillow with this adhesive can still maintain its original performance, and the tape is completely transparent, with almost no impact on the appearance of the air pillow.

When operating, it is necessary to first release the air from the damaged air pillow and temporarily seal the inflation hose. Then, clean the dust and impurities on the surface of the surrounding film at the damaged area and keep it dry. Finally, cut an appropriate length of ETFE tape as needed and apply it to the damaged area. Attention should be paid to ensuring that the adhesive tape is firmly and tightly attached to the surface of the air pillow film material, and there should be no bubbles on the bonding surface, and there should be no warping or other phenomena around the edges of the adhesive tape.

For larger areas of damage that cannot be repaired with tape, it is necessary to remove the air pillow as a whole, remake it according to the same specifications and dimensions, and reinstall it. Another possible damage is an unexpected increase in internal pressure of the air pillow due to system malfunction or other reasons, which exceeds the bearing range of the air pillow, or a serious damage to the air pillow due to quality issues during the manufacturing process. Cracks in the splicing weld seam of the membrane material in the middle of the air pillow or cracks in the weld seam at the edge of the air pillow belong to such causes of damage. Such damage cannot be easily repaired using tape, and the air pillow needs to be removed and replaced as a whole.

When disassembling the air pillow, it is necessary to first disconnect the air source, release the air inside the air pillow, then remove the fixing screws of the air pillow fixture, remove the fixtures around the air pillow, and finally remove, fold, and transport the air pillow back to the factory in a packaging box. After replacing or repairing the air pillow, it can be reinstalled using the same installation process and operation method as when the air pillow was first installed.

If you want to know more about ETFE membrane structure, please add our official WhatsApp: +86-13923448766, or send an email to our official email: yexing@yexinggroup.com. We will provide you with free consulting services 24 hours a day.

How to repair the damaged ETFE membrane structure air pillow?