ENCN

Home / Quality control points of ETFE air pillow processing and combination process

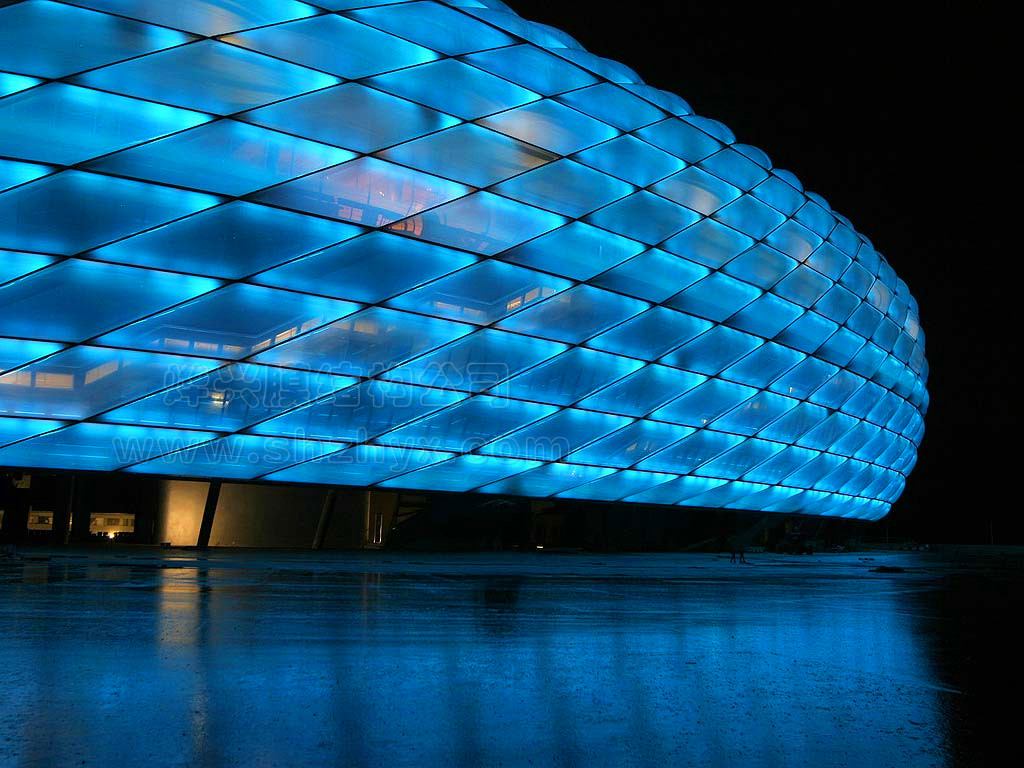

Quality control points of ETFE air pillow processing and combination process

The processing and manufacturing process of ETFE air pillow mainly includes film cutting, diaphragm splicing welding and air pillow combination welding, etc. The main quality inspection and control measures of each operation process are as follows:

First, film cutting

The raw material of the film material is cut into strips of Membrane material. Whether it is cut manually or automatically, its quality should be checked after processing. However, the proportion of manual cutting needs to be checked is larger, and the accuracy of automatic cutting equipment is strong, and only a small proportion of spot checking can be done. For the strip film after manual processing, the main items that should be checked and controlled include:

1, check the consistency of the shape and the drawing, check the processing errors of geometric dimensions such as the length, Angle and diagonal length of each side, so that they are controlled within the permissible deviation range stipulated in the Technical and Quality Acceptance Standards.

2, the cutting edge is smooth and smooth, no flash, burr and so on.

Second, diaphragm production

The process of diaphragm splicing welding includes positioning spot welding and joint continuous welding. The technological parameters used in the welding of film materials are related to the thickness of film materials to be welded and the raw materials of film materials. For films of different thicknesses and different batches, before formal welding, process samples should be made to determine the welding process parameters through process tests. In the process of welding production, no less than three inspection samples should be made along with the batch to carry out spot checks on welding quality. The main quality check items and control points in the diaphragm production process are as follows.

1, positioning welding

① Check whether the spacing of spot welding meets the welding process requirements.

② Check whether the diaphragm lap joint width meets the welding process requirements.

③ Check the outer dimension of the diaphragm formed by positioning welding against the diaphragm combination processing diagram, including the side length size, Angle, diagonal length, etc., so that it is controlled within the permissible deviation range specified in the “Technical and Quality Acceptance Standards”.

- Split welding

① After all the welds of the split welding are welded, check the outline size of the diaphragm again against the drawings to control it within the permissible deviation specified in the Technical and Quality Acceptance Standards.

② Check the appearance of the weld, whether there are impurities, bubbles, over-melting, missed welding and other defects.

③ The tensile test of the welding inspection template made with the batch is carried out to check whether the welding strength meets the design requirements.

Three, air pillow production

The production process of air pillow includes diaphragm overlap and positioning welding, side band positioning welding, air pillow peripheral welding and other procedures. The main quality check items and control measures in the process are as follows.

1, the ground and positioning of the diaphragm spot welding

① After the diaphragm is superimposed and spot-welded, check whether the edges are aligned.

② Check the corresponding position of the split weld of each layer of diaphragm, which should comply with the relevant provisions of the “Technical and Quality Acceptance Standards”.

③ Check the position of the positioning solder joint, including spacing, margin, etc., whether it meets the welding process requirements.

(4) Check the dimensions of the air pillow formed by positioning welding against the gas pillow combination processing diagram, including the side length size, Angle, diagonal length, etc., so that it is controlled within the permissible deviation range specified in the “Technical and quality Acceptance Standards”.

2, sideband combination and positioning welding

① Check the correctness of the position of each side band. The outer edge of the side band is parallel to the outer edge of the air pillow diaphragm, and the spacing meets the design requirements.

② Check the outline size of the air pillow belt against the drawing, and control the deviation of its side length, Angle, diagonal line within the permissible deviation range specified in the Technical and Quality Acceptance Standards.

- Continuous welding around the air pillow

① After all the continuous welds around the air pillow are welded, check the external dimensions of the air pillow at the outer edge of the side strip again against the drawings, including side length, Angle, diagonal line, etc., and control its deviation within the permissible deviation range specified in the Technical and Quality Acceptance Standards.

② Check whether the appearance and width of the weld meet the requirements, and whether there are defects such as impurities, bubbles, over-melting, and missing welding.

③ Check the continuity of the peripheral weld, especially at the corner weld joint, whether the weld is continuous and whether there is a break point.

④ Check the V-shaped incision at the corner joint of the air pillow, and whether the distance between the tip of the incision and the weld meets the requirements.

⑤ Carry out tensile test on the welding inspection template made with the batch to check whether the welding strength meets the design requirements.

4, air pillow overall final inspection

Clamp is installed around the air pillow and fixed on the steel frame for inspection. Connect the temporary gas tube, fill the air into the air pillow, make its internal pressure reach or exceed the actual working pressure, and maintain the pressure for a certain time. Check the welding strength and sealing of each weld of the air pillow, and check whether the height of the air pillow meets the design requirements.

If you want to know more about membrane structure, please add our official WhatsApp: +86-13923448766, or send an email to our official email: yexing@yexinggroup.com. welcome visit our webist :https://www.yexingms.com/, facebook :https://www.facebook.com/profile.php?id=100095229491041, and our official Instgram :https://www.instagram.com/yexinggroup/,We will provide you with free consulting services 24 hours a day.

Quality control points of ETFE air pillow processing and combination process

Recent News

-

Control process of membrane structure quality

-

Yexing Membrane Structure Introduction What is air pillow membrane structure

-

What are the advantages of membrane structure tent hotels?

-

Yexing—Comprehensive Commercial Membrane Structure Project in the North District of Dongfang Wanhui City, Nanjing