ENCN

Home / The meaning of PTFE membrane structural materials

The meaning of PTFE membrane structural materials

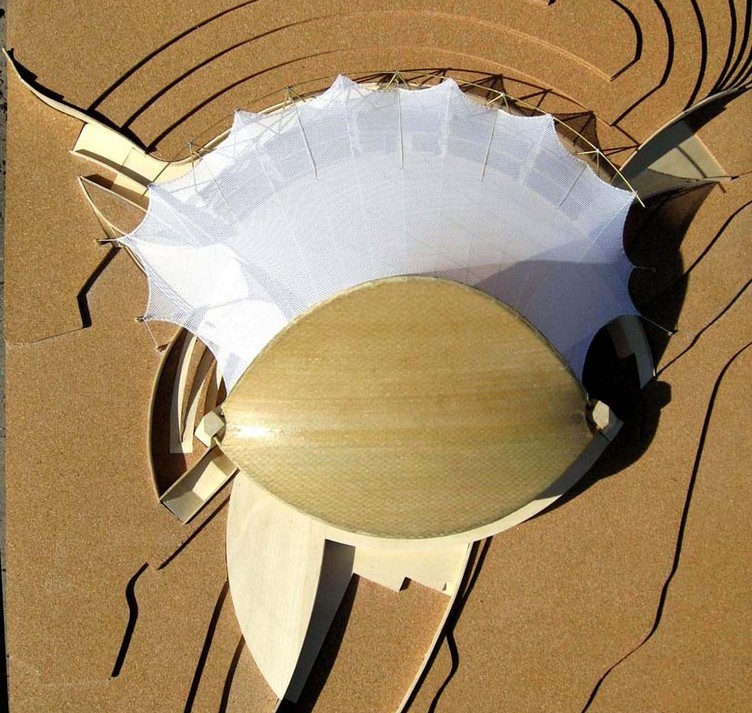

ETFE membrane structural material (permanent membrane) refers to a composite material formed by coating PTFE (polytetrafluoroethylene) on a substrate woven from an extremely fine glass fiber.

The characteristics of PTFE membrane structural materials

The biggest characteristics of PTFE membrane structural materials are high strength, good durability, fire resistance, good self-cleaning, not affected by ultraviolet light, and more than 25 years of service life. It has a high light transmittance, a light transmittance of 13%, a thermal reflectivity of 73%, and a little heat absorption of PTFE film. It is precisely because of the invention of this epoch-making membrane material that the membrane structure building has become a modern permanent building.

The finest fiberglass

PTFE film structural material used in the glass fiber is the world’s thinnest variety, PTFE film is also known as Beta grade glass fiber, has good folding and bending resistance, to the production, processing and installation of film material to bring the greatest security.

Very good chemical stability

PTFE membrane structural materials have a high degree of chemical stability and can withstand all strong acids including aqua rega, strong oxidants, reducing agents and various organic solvents in addition to molten alkali metals, fluorinated media and sodium hydroxide above 300 ° C.

Very good self-cleaning

PTFE is invented by the DuPont Company, commonly known as “Teflon”, (civil use in “non-stick pan”) has a prominent non-sticky, PTFE film it almost does not stick to any dust, known solid materials can not adhere to its surface, it is a solid material with minimal surface energy.

Unique coating process

PTFE film material uses a unique dip coating and leveling drying technology, so that PTFE soaked glass fiber, after sintering at high temperature, PTFE and glass fiber completely combined, fused in one. PTFE film under sunlight, after absorbing ultraviolet light, the glass fiber gradually fades, PTFE film gradually becomes white within 3-6 months, and will become more and more white in the future use process.

If you want to know more about membrane structure, please add our official WhatsApp: +86-13923448766, or send an email to our official email: yexing@yexinggroup.com. welcome visit our webist :https://www.yexingms.com/, facebook :https://www.facebook.com/profile.php?id=100095229491041, and our official Instgram :https://www.instagram.com/yexinggroup/,We will provide you with free consulting services 24 hours a day.

The meaning of PTFE membrane structural materials