ENCN

Home / Who knew that foundation pits could be constructed this way? The new fully enclosed technology has covered the whole country.

Who knew that foundation pits could be constructed this way? The new fully enclosed technology has covered the whole country.

The gas membrane technology for foundation pit has been popularized and applied in Chengdu, Beijing and Shenzhen. Recently, the gas pillow type foundation pit membrane has been completed in the Ba’an Traffic Police Brigade Project of the Southern Company of China Construction Eighth Engineering Bureau; before this, the underground parking garage project of the Protection Area of Shijingshan in Beijing has completed the gas rib type foundation pit gas membrane……

Shenzhen Baoan Traffic Police Brigade Project Air Cushion Type Pit Air Film

The air membrane of the foundation pit, simply speaking, is an inflated membrane structure built with high-strength membrane materials. The air membrane of the foundation pit not only effectively reduce the emission of harmful gases and coarse particulate matter, but also significantly reduce the noise generated by the construction operation. In the area covered by the air membrane the foundation pit, the dust can be reduced by more than 90% year-on-year, and the noise can be reduced by 60% year-on-. ”Meanwhile, with the cooperation of sprinkling, ventilation and lighting systems, the air membrane “protection umbrella” also provides a comfortable working field with constant temperature and for construction workers, reducing the delay of the construction period and the consumption of resources caused by bad weather and repeated covering, and truly achieving a coordinated unity of “promoting progress” “not disturbing the people”.

Three types of air film for foundation pit:

- Air-supported type: Maintain positive pressure inside the membrane through continuous air supply, thereby forming a selfsupporting dome structure. This type does not require an internal skeleton.

- Air pillow type: Composed of multiple independently inflated air pillows, each air pillow is a double- membrane structure.

- Air beam type: Use the air-filled arch ribs to form the air beam as the skeleton, and cover the membrane on the outside to form a rigid structure.

The air film of the foundation pit extends from Beijing to the whole country

In November 2023, the first large-scale foundation pit air project in Beijing, the Sandong Monument Comprehensive Building Project, covering an area of more than 4,000 square meters, is the first large-span foundation air film project in Beijing with both the width and length of the foundation pit exceeding 100 meters, which can reduce construction dust by more than 90%

Then, the air membrane of the foundation pit was introduced and used in many other regions in China, including but not limited to Shenzhen, Shijiazhuang Wuhan and other cities….

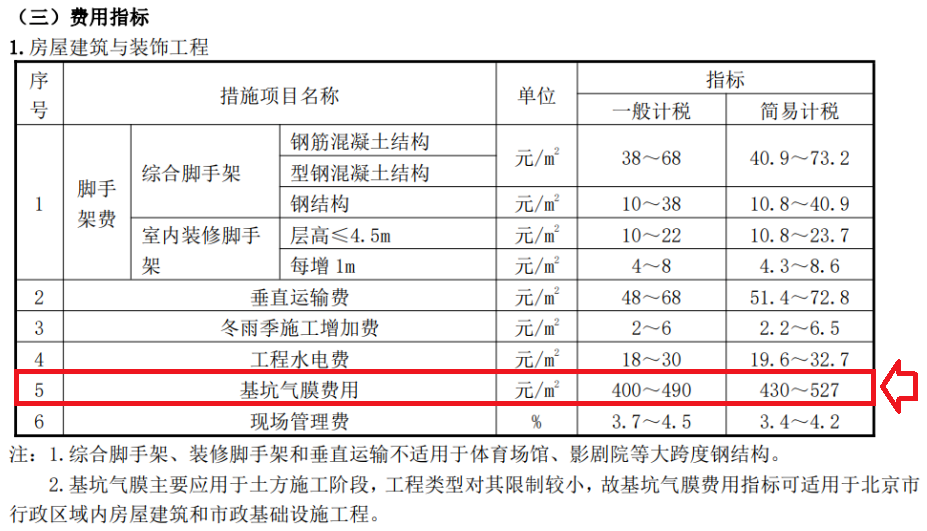

Cost Standard: Beijing Municipal Commission of Urban-rural Development and Housing Construction has taken the lead in releasing the “Guidance for the of Air Membrane Technology in Building Construction and Municipal Infrastructure Engineering Pit in 2024, which helps to promote the successful experience of Beijing City nationwide and accelerates the promotion application of air membrane technology in the field of green construction. Beijing Municipal Commission of Urban-rural Development and Housing Construction also included the cost index of air membrane in in the “Beijing Engineering Cost Information” in 2024: general tax calculation 400~490 RMB/m2, simple tax calculation430~527 RMB/m2 (m2 is the horizontal projection area of the air membrane). This cost index is applicable to the air-supported membrane in pit within the administrative area of Beijing City, providing the basis for the preparation of the maximum bidding price limit for both the tenderer and the bidder, and is also reference for other regions in the country

The gas membrane foundation pit increases the one-time investment of the project, but the comprehensive benefits are obvious: First, environmental benefits, reducing the cost of bare sites and dust control measures; second, technical benefits, winter concrete curing can save insulation covering measures and reduce seasonal construction costs; third, progress benefits, it can avoid in the construction period caused by weather and other reasons, shorten the construction period and start early to benefit early; fourth, turnover benefits, standardized products are easy to disassemble and be reused, and the cost is amortized step by step; fifth, social benefits, it promotes the development of the construction industry towards industrialized construction, and enhances the image of green construction on the construction site.

Who knew that foundation pits could be constructed this way? The new fully enclosed technology has covered the whole country.

Recent News

-

ETFE membrane structure丨Borderless theater between Cangshan Mountain and Erhai Lake

-

Membrane structure丨Between left and right strokes, through the bamboo beams

-

Exploring the Development and Application of New Materials

-

Architectural renderings of ETFE air pillow membrane structure at Yexing Airdam Railway station