Director of Yexing Membrane Structure Design

ENCN

ENCN

Home / Projects / Leshan Olympic Center PTFE membrane structure venue project

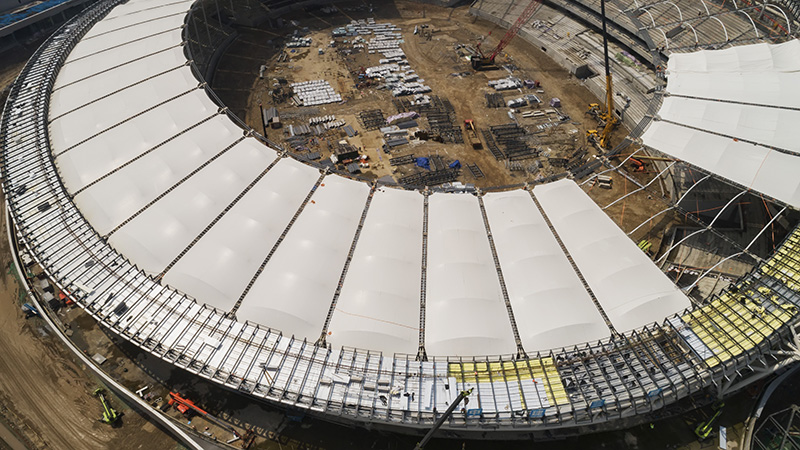

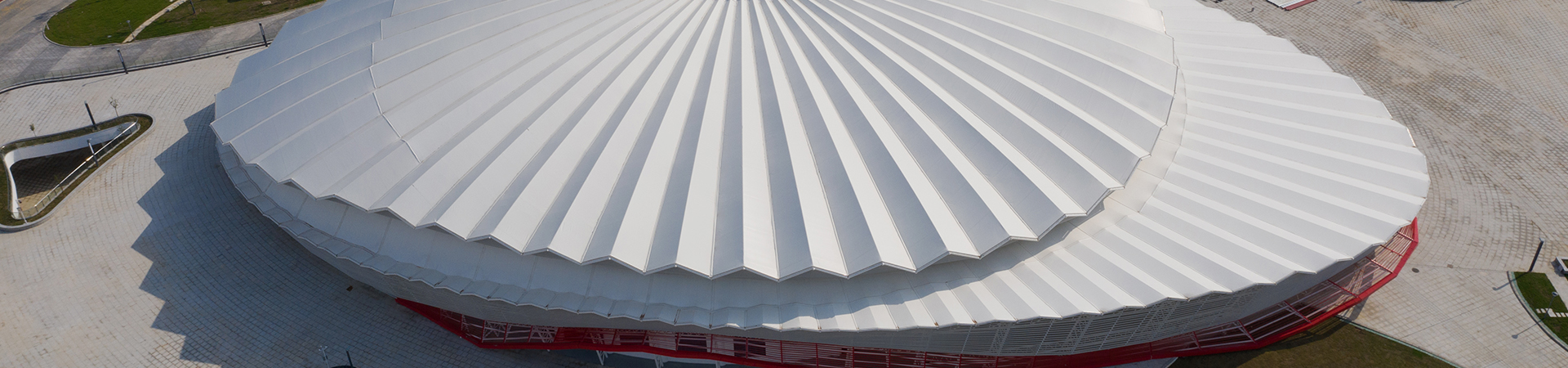

As the main venue of the 14th Sichuan Games in 2022, Leshan Olympic Center will mainly build “one game, three venues”, supporting buildings, underground garage, etc. Among them, “One Stadium, Three Pavilions” includes the main stadium with 30000 seats and a construction area of approximately 46000 square meters; The sports hall has 6000 seats and a building area of approximately 27000 square meters; The Natatorium has 300 seats, with a floor area of about 22000 square meters; The comprehensive training center has a building area of approximately 29000 square meters, an underground garage of approximately 55000 square meters, and a total of 1580 parking spaces on the roof.

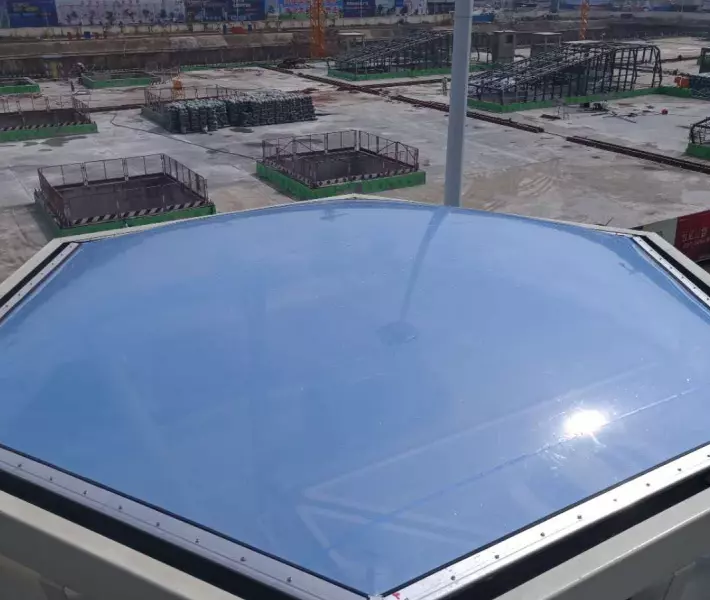

Engineering features: The Leshan Olympic Sports Center venue is a flexible suspension system supported PTFE membrane structure roof, which can be seen as an irregular oval shape overall. The cable structure of this project is a hybrid structure of single and double layer cable nets, belonging to a new type of structural system. The construction process is complex, manifested as: the internal force of the cables is large, and the maximum unbalanced force of some cable clamps exceeds 750 tons (currently the largest in the construction of sports venues). The design and production of cable clamps are difficult, and the stability of the steel structure must be ensured during the cable system forming process. It can be said that this is an innovative project that relies on China’s material and construction strength.

Leshan Olympic Center PTFE membrane structure venue project

| Date | 2022 |

|---|---|

| Location | Sichuang, China |

| Size | 31,000 m² |

| Membrane | White PTFE film |

| Structure | Framework Membrane Structure |

PTFE film on glass fiber fabric creates durable roofs with over 30 years of lifespan, ideal for sports venues, commercial facilities, and transportation structures.

View Details

The steel structure of the Yexing project has been carefully constructed and installed by force analysis and structural calculation by STAAD, SW, ANSYS, RHINO, 3D3S and other software, and has become a permanent building structure with a life of at least 50 years.

Yexing has 19 years of professional installation experience in steel structure and 15 years of membrane structure, and more than 400+ landing projects at home and abroad are the greatest affirmation of Yexing's construction level.

Imported top brand membrane material, with high tensile strength, large bearing capacity, long service life, bearing capacity per square can reach 300-500KG, wind resistance level 12 or more, upper, seismic resistance above 7 grade.

Yexing adopts imported intersecting wire cutting equipment and first-stream carbon dioxide protection welding equipment, which has good precision, high efficiency, and electric welder certificate. On-the-job, strict assessment, outstanding craftsmanship.

The anti-corrosion and anti-rust process of Yexing film structure is controlled layer by layer through 8 processes: shot blasting, rust removal, sandblasting, 2 primers, intermediate paints and 2 topcoats, and strictly abide by the quality.

Yexing membrane structure accessories are high-quality, all stainless steel or national standard hot-dip galvanized customized standard parts, PE cables are provided by Juli Group, high vanadium cables are provided by Jianlang Group.