Director of Yexing Membrane Structure Design

ENCN

ENCN

Home / Projects / Membrane Structural engineering of Shanghai Pudong Football Stadium

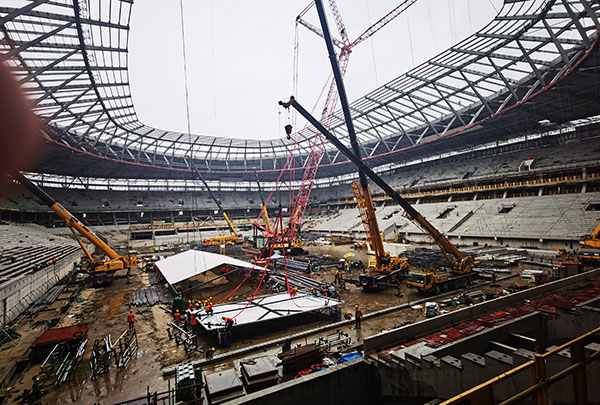

The Pudong Football Stadium project is one of the important tasks of sports infrastructure construction in Shanghai during the “13th Five Year Plan” period, and is listed as a major construction project in Shanghai in 2018. This is the first modern professional football field tailored for a Chinese Super League club in China, meeting the various competition needs of FIFA. The building area is 139304 square meters, with a fixed seating capacity of 33765 seats. The roof of the stadium adopts a prestressed spoke shaped tensioning system, which is characterized by a combination of steel structure and cable mesh, making it more lightweight.

In this beautiful venue known as the “white porcelain bowl”, it is necessary to install nearly 30000 square meters of membrane structure lining on the inner wall of the venue, which is more than 40 meters above the ground. Through precise data measurement and analysis, Ye Xing takes into account factors such as engineering aesthetics, construction convenience, and cross operation with other professions, and divides the entire interior wall of the venue into 276 units of varying sizes (with a minimum of 48 square meters for a single membrane unit and a maximum of 150 square meters), The membrane unit is first tensioned and modulated on the ground platform, and then fixed by a fully automatic CNC balance hoist.

Membrane Structural engineering of Shanghai Pudong Football Stadium

| Date | 2020 |

|---|---|

| Location | Shanghai, China |

| Size | 139,304 m² |

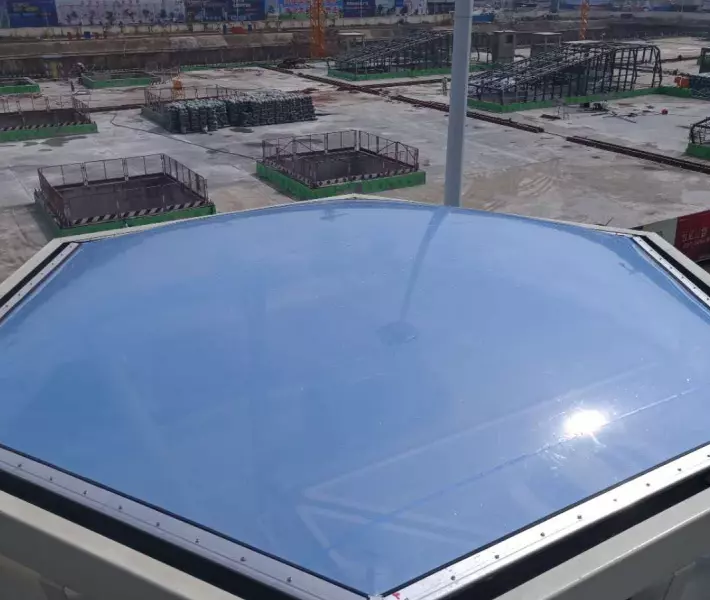

| Membrane | White PVDF film |

| Structure | Framework Membrane Structure |

The steel structure of the Yexing project has been carefully constructed and installed by force analysis and structural calculation by STAAD, SW, ANSYS, RHINO, 3D3S and other software, and has become a permanent building structure with a life of at least 50 years.

Yexing has 19 years of professional installation experience in steel structure and 15 years of membrane structure, and more than 400+ landing projects at home and abroad are the greatest affirmation of Yexing's construction level.

Imported top brand membrane material, with high tensile strength, large bearing capacity, long service life, bearing capacity per square can reach 300-500KG, wind resistance level 12 or more, upper, seismic resistance above 7 grade.

Yexing adopts imported intersecting wire cutting equipment and first-stream carbon dioxide protection welding equipment, which has good precision, high efficiency, and electric welder certificate. On-the-job, strict assessment, outstanding craftsmanship.

The anti-corrosion and anti-rust process of Yexing film structure is controlled layer by layer through 8 processes: shot blasting, rust removal, sandblasting, 2 primers, intermediate paints and 2 topcoats, and strictly abide by the quality.

Yexing membrane structure accessories are high-quality, all stainless steel or national standard hot-dip galvanized customized standard parts, PE cables are provided by Juli Group, high vanadium cables are provided by Jianlang Group.