Vice President of Engineering Department

ENCN

ENCN

Home / Service / Engineering

Our experienced architects and engineers will analyze the design with special software that can design fabric membrane, cables and steel frames. Taking into account the external inputs of natural climates such as wind, rain and other related loads, all outputs will be checked against all relevant standards to ensure safety, feasibility, optimization and economy, long-term reliability to provide the best programs. Our expertise, dedication and creativity, combined with state-of-the-art technology, will bring you results – your project is a complete success.

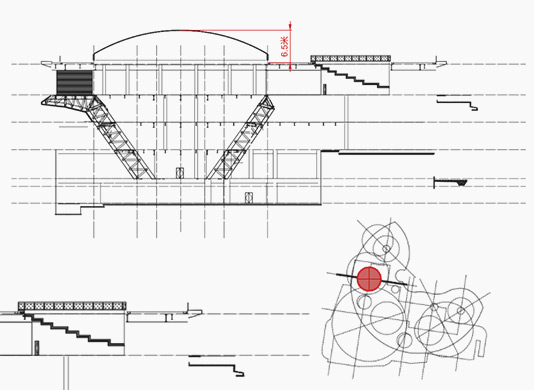

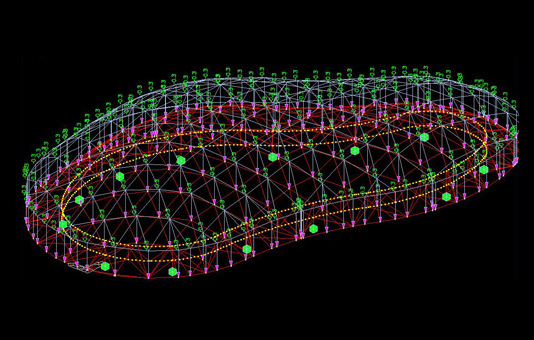

According to the design, we first construct of the 1:1 numerical model to simulate the processing and installation process, to find out the defects existing in the design and carry out the optimization and transformation.Reduce the variety of errors in processing, avoid the manufacturers to make mistakes.

The goal of membrane construction is to create the perfect art building and the most cost-effective! We have a professional team to provide your project with a comprehensive solution that is artistic, economical, and eco-friendly.

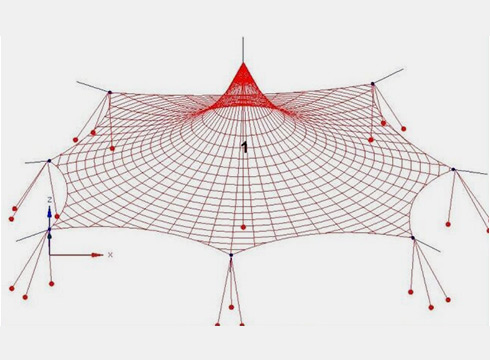

The main material used in the membrane structure itself does not have a basic stiffness and shape. It does not have a load bearing capacity in a natural state. Pre-stressing the membrane is obtain the rigidity and shape for structural bearing. Therefore, the first design process is morphological analysis, looking for structural shape that meet architectural modeling and functional requirements and correspond to a self-balancing prestress distribution state.

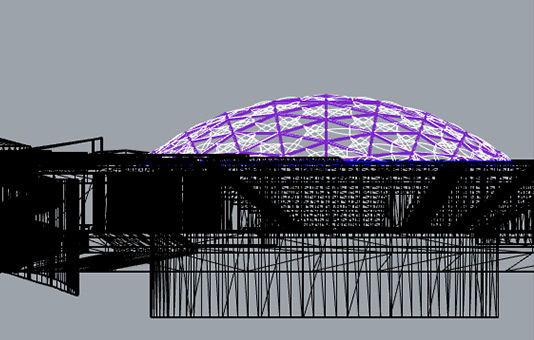

Load effect analysis and design of supporting structure

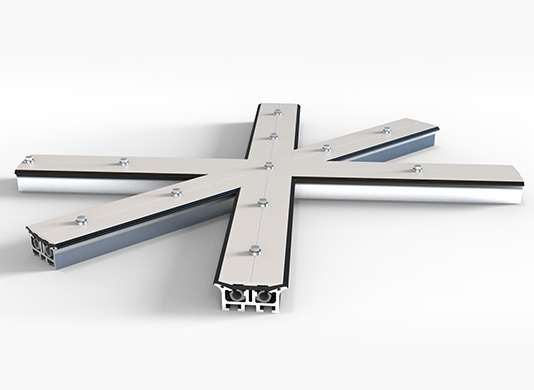

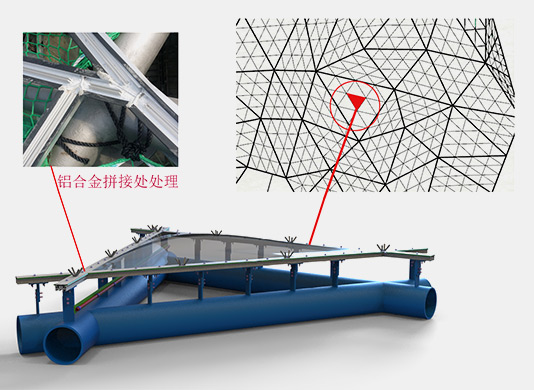

1. The visual effects of nodes and connections are related to people’s aesthetic perception of space and the expression of social and cultural values. Structural logic and art are equally important in connection and node design, so node and connection design is one of the keys to the overall structural design.The processing of connections and nodes also reflects the designer’s understanding of structural logic and material properties.

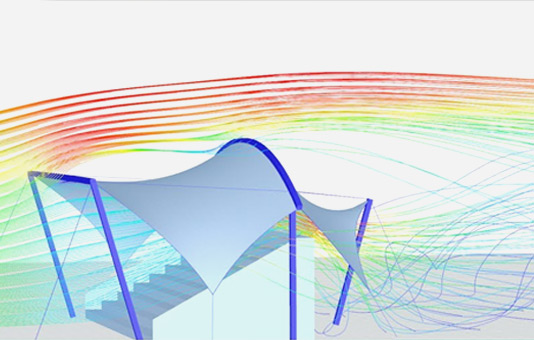

2. The force analysis of the membrane structure, should consider various load conditions, such as full load, half-span uniform load and different directions of action, etc.. We use profession Finite Element Analysis software to perform simulation analysis of each node and verify its strength. Calculate the displacement, stress, etc. of the structure under the most unfavorable conditions, check whether the strength of the material (including the film and cable) and the deformation of the structure meet the requirements of its use. When designing the structure, the conditions should be integrated to output the best safe, economical and aesthetic results.

If you need more information about our membrane structure, please feel free to contact us, we will provide you with professional personnel for service, we will reply promptly after receiving the information.

Stress analysis of the support structure – details determine success or failure! 1. The support structure is the thin link of the building. The safe and reliable support structure design is the guarantee of the overall structure safety. 2. We use finite element software to perform simulation analysis on each support structure to verify its strength.

In the absence of wind tunnel test data, numerical calculations provide calculations that provide actual conditions for wind load calculations. According to the building environment and climate, the airflow around the building and the wind pressure distribution on the surface of the maintenance member are solved under the wind load.

The membrane cutting analysis applied to the membrane structural surface which meets the design requirements obtained from the morphological analysis. The membrane structure of the morphological analysis and the cutting analysis is the basis of the load analysis (the main axis direction of the membrane should be considered in the load analysis). The accuracy of the analysis directly affects the approximation of the actual surface obtained to the theoretical surface of the morphological analysis. 2. The determination of the membrane cutting line is affected by various factors, such as the influence of the arrangement of the cutting line on the aesthetics of the entire membrane structure; the width of the cutting strip after the unfolding cannot be greater than the width of the film to improve the utilization of the fabric membrane.

Through the visual presentation of the state of the components in the installation step, it provides a reference for ensuring construction safety or installation quality.