Senior Designer of Membrane Structures

ENCN

ENCN

Home / Service / Environmental

YEXING is committed to developing and delivering systems that add economic, environmental and social value. Furthermore, we aim to positively impact communities, the industry, and reduce our overall carbon footprint.

We continue our efforts to protect the environment by controlling pollutant emissions during production and reducing energy consumption during the transportation of our products.

In addition, we are committed to the development of human resources and product quality to promote the sustainable development of our company.

We strive to be an environmentally friendly company, introducing the concepts of recycling production and resource reuse into our production operations. Through comprehensive control of waste recycling and pollutant emissions, we are continuing to move toward a future that combines low carbon and environmental protection.

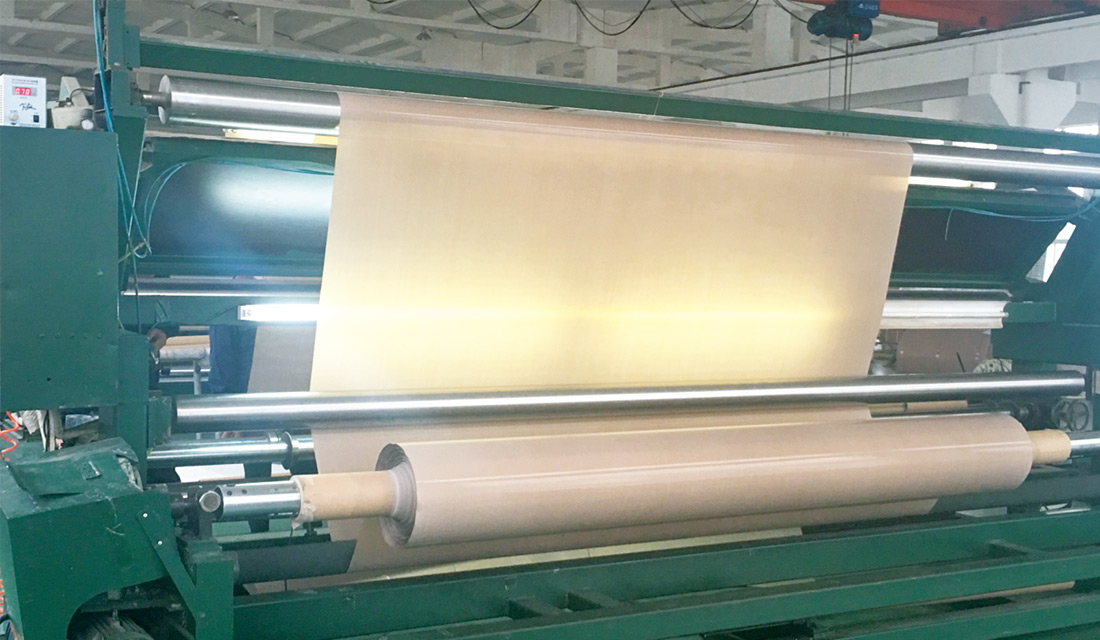

We take a granular resin, heat it up and then extrude it into films on special extruder machines. Further, to adjust the machine output to the exact required product specifications takes some time. The material that is extruded in this short adjustment phase is cut off and directly fed into a shredding machine. Hence, the small shredded chips of membrane can then be mixed with fresh resin for the extrusion of the next batch of membrane.

The membrane are delivered to one of the factories on large rolls with several hundred meters of raw film each. Further, by using automated plotting tables, the membrane are marked and cut into sheets, which subsequently are welded into project specific panels.

Further, while we put a great effort into reducing cut-offs by using custom made nesting software tools, a small percentage of waste material cannot be avoided. Henceforth, these cut-offs are carefully collected by the factory personnel. Moreover, the production team at YEXING is committed to 100% recycling, i.e. not leaving any snippets of membrane film on the floor nor to send any leftovers to the landfill. Consequently, in order for them to be forwarded to a recycling plant, the collected snippets are compacted. As this material is potentially contaminated with coatings or dust, it’s not used for the production of new architectural films, but for the production of valves, flanges, flexible pipes, and other attachment parts for the membrane system. Wherever the unique material characteristics of membrane such as the long-term UV stability or the resistance to chemicals, are required.

If you need more information about our membrane structure, please feel free to contact us, we will provide you with professional personnel for service, we will reply promptly after receiving the information.